As the world shifts towards sustainable transportation, electric vehicle (EV) battery technologies have become central to achieving global environmental goals. The demand for cleaner, more efficient transportation has never been higher, with electric vehicles at the forefront of this transition. As automakers ramp up production targets, breakthroughs in EV battery technology are helping to address critical challenges such as energy density, charging speed, and lifecycle sustainability.

This blog delves into the most significant advancements in EV battery technologies, market trends, challenges, and investment opportunities. We will explore how these new innovations in battery technology are reshaping the automotive industry and how companies can stay ahead using platforms like Entrapeer to streamline their decision-making processes.

The EV Battery Sector: A Dynamic and Rapidly Evolving Market

The electric vehicle (EV) battery market has rapidly grown into one of the most critical components of the broader transition to sustainable transportation. The growing demand for EVs is primarily driven by the increasing awareness of climate change and the need to reduce greenhouse gas emissions. However, this shift would not be possible without the ongoing advancements in battery technology, which enable electric vehicles to travel further, charge faster, and last longer.

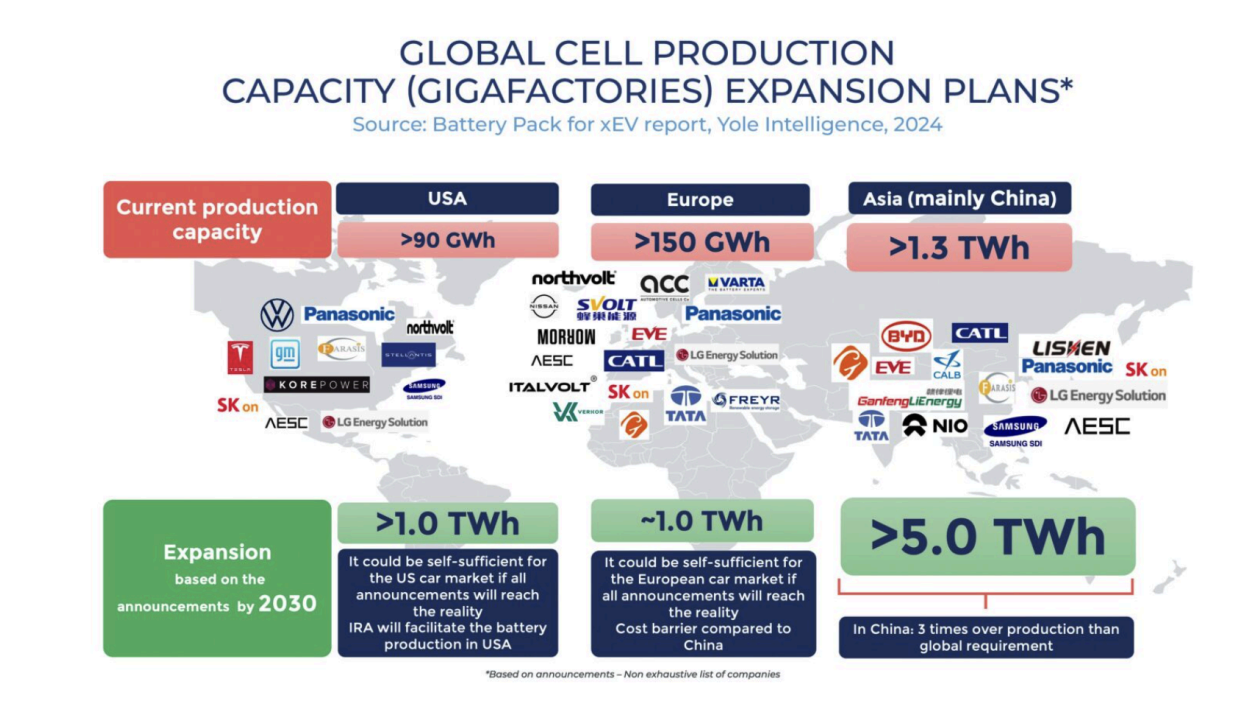

According to recent market analysis, the global demand for EV battery technology is expected to grow at a compound annual growth rate (CAGR) of 22.8% from 2022 to 2030, underscoring the vital role that these technologies play in the future of mobility. Major automakers, including Tesla, General Motors, Ford, and Volkswagen, have announced multi-billion-dollar investments in electric vehicle production, with plans to manufacture millions of EVs annually by 2030.

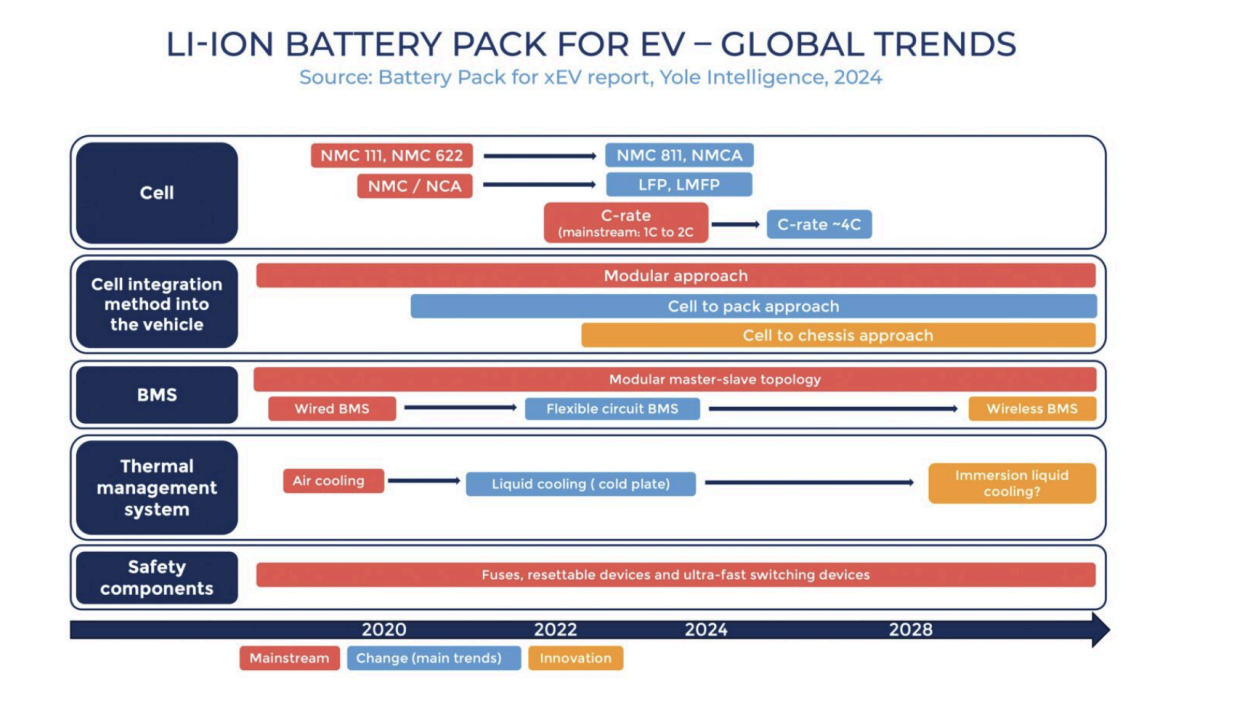

However, behind this growth lies a complex ecosystem of subcategories and supporting technologies:

- Battery Cell Manufacturing: The production of individual battery cells, which store energy and power EVs.

- Battery Pack Assembly: Combining multiple cells into packs to provide the required energy storage for vehicles.

- Battery Management Systems (BMS): Sophisticated systems designed to monitor and optimize battery performance, prolonging battery life and improving efficiency.

- Battery Recycling and Second-Life Applications: Critical technologies focused on extending the lifecycle of batteries and recycling raw materials to reduce environmental impact.

Technological Advancements in EV Battery Technologies

The relentless drive for higher performance, better efficiency, and sustainability in EV batteries has led to a flurry of innovations. Several cutting-edge technologies are poised to reshape the EV landscape in the coming years.

1. Solid-State Batteries: The Next Generation

Solid-state batteries represent one of the most promising advancements in EV battery technology. Unlike traditional lithium-ion batteries that use liquid electrolytes, solid-state batteries use solid electrolytes, which offer several key advantages:

- Higher Energy Density: Solid-state batteries can store more energy per unit of volume, allowing EVs to travel longer distances on a single charge.

- Improved Safety: These batteries are less prone to overheating, reducing the risk of thermal runaway and fires.

- Faster Charging Times: Solid-state batteries can charge faster than their lithium-ion counterparts, with some early prototypes showing the ability to charge up to 80% in just 10 minutes.

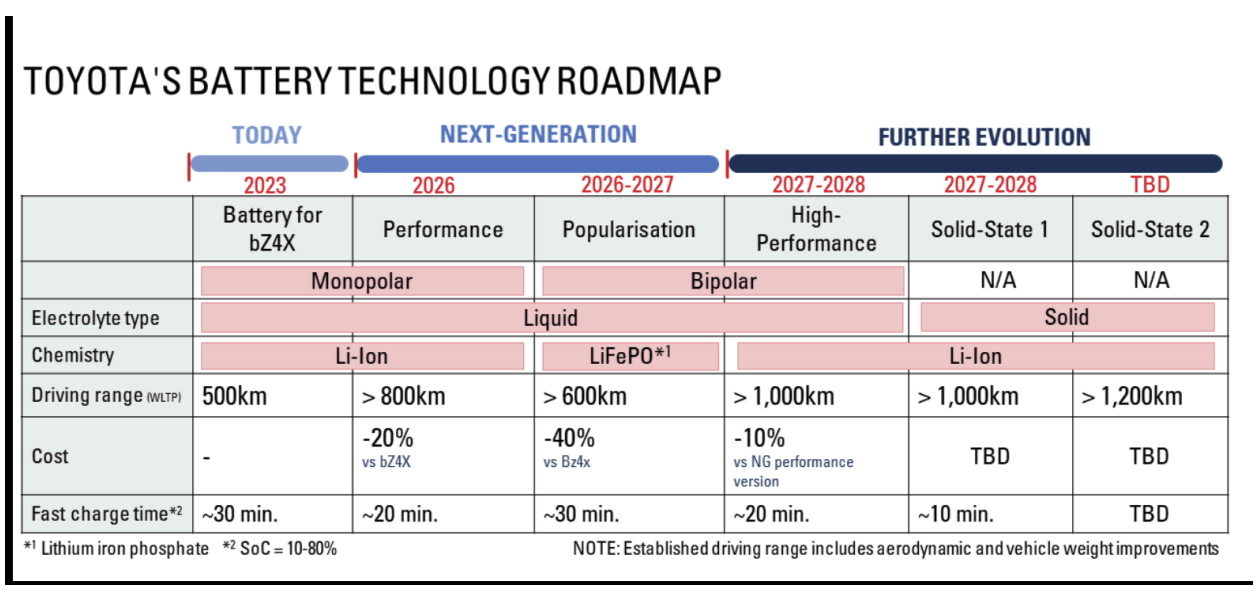

Companies like QuantumScape and Solid Power are leading the way in the development of solid-state batteries. QuantumScape, in particular, has garnered significant attention with its plan to commercialize solid-state batteries by 2028, offering cars with ranges of up to 1,000 kilometers. Toyota is also making significant strides, with plans to release a solid-state battery-powered vehicle capable of 1,000 kilometers of range and a 10-minute recharge by 2027.

While solid-state batteries hold immense potential, their widespread adoption faces challenges such as high production costs and difficulties in scaling up manufacturing. However, as research and development continue, these hurdles are expected to be overcome, paving the way for the next generation of EVs.

2. Silicon-Based Anodes: Pushing Boundaries

Another critical advancement in battery technology is the introduction of silicon-based anodes. Traditional lithium-ion batteries use graphite as the primary anode material, but researchers and companies are now exploring the use of silicon to enhance battery performance. Silicon anodes can store significantly more lithium ions than graphite, allowing for:

- Higher Capacity: Silicon anodes can store up to 10 times more energy, meaning EVs can achieve greater range on a single charge.

- Faster Charging: Silicon-based anodes enable faster charging times, addressing one of the major barriers to widespread EV adoption.

Panasonic and Sila Nanotechnologies have been working together to integrate silicon anodes into lithium-ion batteries, with commercial production expected by 2024. Additionally, Group14 Technologies has been developing high-performance silicon anode materials, which promise faster charging and greater efficiency in the coming years.

The use of silicon anodes could represent a significant leap forward in battery performance, making EVs more practical for long-distance travel and more competitive with traditional internal combustion engine vehicles.

3. Dry-Coating Manufacturing: Efficiency and Sustainability

One of the biggest challenges in producing EV batteries is the high energy consumption and environmental impact of traditional manufacturing processes. To address this, companies like LG Energy Solution have been developing dry-coating technologies that significantly reduce energy consumption during battery production. This innovative process eliminates the need for energy-intensive wet coating, reducing production costs by up to 25% and cutting energy usage by 80%.

By making the manufacturing process more efficient and sustainable, dry-coating technology could help lower the overall cost of EV batteries, making electric vehicles more affordable for consumers and helping manufacturers meet global sustainability goals.

4. AI and Machine Learning in Battery Management

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing battery management systems (BMS), providing real-time insights into battery performance, charging patterns, and energy consumption. Companies like Electra Vehicles have developed AI-powered solutions that optimize battery efficiency by predicting range and adjusting energy use based on real-time data.

AI-driven BMS can help extend battery life, prevent overcharging, and improve overall performance. This is particularly valuable as EV manufacturers aim to enhance vehicle range and reliability. Furthermore, AI algorithms are being used to optimize charging infrastructure, ensuring that EVs can be charged more efficiently and conveniently at scale.

Major Challenges Facing the EV Battery Industry

Despite the significant progress in EV battery technology, several key challenges remain that could slow the transition to an electric future.

1. Supply Chain Instability and Raw Material Constraints

One of the most pressing challenges facing the EV battery sector is the instability of the supply chain for critical raw materials such as lithium, cobalt, and nickel. These materials are essential for the production of lithium-ion batteries, but their extraction is often limited by geopolitical tensions, environmental concerns, and fluctuating market prices.

For example, lithium extraction in regions like South America and Africa has been subject to political instability, while growing demand has caused supply bottlenecks. Furthermore, cobalt mining, particularly in the Democratic Republic of the Congo, has raised ethical concerns due to poor labor practices and environmental degradation.

Efforts are underway to develop alternative sources of these materials and improve recycling processes. Direct Lithium Extraction (DLE), a technology being developed by companies like ExxonMobil and SK On, offers a more sustainable and efficient way to extract lithium from underground saltwater deposits. Additionally, recycling innovations, such as Redwood Materials’ hydrometallurgical recycling, can recover over 95% of valuable metals from used batteries, reducing dependence on new raw materials.

2. Charging Infrastructure and Range Anxiety

While advancements in battery technology have significantly improved EV range, range anxiety—the fear of running out of power before reaching a charging station—remains a significant barrier to widespread adoption. The uneven distribution of charging infrastructure exacerbates this issue, particularly in rural areas and emerging markets.

Governments and private companies are investing heavily in expanding EV charging networks. In the U.S., the Bipartisan Infrastructure Law has allocated billions to develop a nationwide EV charging network, with a focus on underserved areas. Meanwhile, companies like Tesla, Electrify America, and ChargePoint are deploying fast-charging stations that can significantly reduce charging times.

Innovative solutions like wireless charging are also emerging, making EV charging more convenient and eliminating the need for traditional charging stations. WiTricity, a pioneer in wireless charging, is developing systems that allow EVs to be charged by simply parking over a charging pad, streamlining the charging process for consumers.

Future Trends: Investment Opportunities and Market Growth

The global EV battery market is experiencing unprecedented growth, with demand for battery electric vehicles (BEVs) projected to drive the need for over 1,600 GWh of battery capacity by 2029, according to Yole Group. This growth represents a significant opportunity for investors and companies looking to capitalize on the shift towards electrification.

1. Strategic Partnerships and Supply Chain Integration

As the EV market expands, strategic partnerships are becoming increasingly important. Major automakers are partnering with battery manufacturers to ensure a stable supply of advanced batteries. For example, Renault, LG Energy Solution, and CATL have formed alliances to develop lithium iron phosphate (LFP) batteries for mass-market EVs in Europe. These batteries offer lower costs and improved safety compared to traditional lithium-ion batteries, making them an attractive option for affordable electric vehicles.

2. Diversification of Battery Chemistries

While lithium-ion batteries currently dominate the market, alternative battery chemistries are gaining traction. Lithium iron phosphate (LFP) and sodium-ion batteries are emerging as viable alternatives, particularly for applications where cost and safety are paramount. Sodium-ion batteries, for example, are abundant, lower-cost, and less prone to overheating than lithium-ion batteries, making them an attractive option for grid-scale energy storage.

The focus on solid-state batteries is also intensifying, with companies like Samsung and Toyota racing to bring commercial solid-state batteries to market. Solid-state technology could revolutionize EVs by providing greater energy density, faster charging, and improved safety, potentially phasing out traditional lithium-ion chemistries.

Entrapeer’s Role in Driving Innovation

Navigating the complexities of the EV battery market requires real-time insights, data-driven decision-making, and the ability to identify and act on emerging trends. This is where Entrapeer excels. By leveraging our AI-powered platform, businesses can access the latest market research, competitor analysis, and predictive intelligence to make informed decisions.

Our platform allows users to:

- Explore emerging technologies: Use our AI-driven Use Case Discovery Tool to identify cutting-edge battery technologies relevant to your business.

- Benchmark against competitors: Our Competitor Intelligence feature helps companies understand how industry leaders are leveraging battery technologies, providing insights into best practices and strategies.

- Stay ahead of trends: Entrapeer’s predictive analytics offer real-time insights into the future direction of the EV battery market, ensuring you stay one step ahead of the competition.

Conclusion: Paving the Way for a Sustainable Future

The future of EV battery technology is incredibly bright. As innovations in solid-state batteries, silicon anodes, and sustainable manufacturing continue to reshape the market, electric vehicles are poised to become the standard mode of transportation. While challenges remain, including supply chain constraints and charging infrastructure, the ongoing advancements in battery technology offer solutions that will ultimately overcome these hurdles.

For companies looking to stay ahead in this fast-evolving industry, partnering with Entrapeer provides the tools, insights, and connections needed to succeed. Request a demo or sign up today to see how Entrapeer can help your business lead the charge in the world of EV battery technologies.

Solid-state batteries are considered the most advanced technology, offering higher energy density, faster charging, and improved safety compared to lithium-ion batteries.

Silicon anodes can store more lithium ions than traditional graphite, leading to greater battery capacity and faster charging times, which translates to longer EV ranges and more convenient charging.

Battery recycling reduces the need for new raw materials, minimizes environmental damage from mining, and lowers the carbon footprint of battery production by recovering valuable metals like lithium and cobalt.

Key challenges include supply chain instability, high production costs, and the need for expanded charging infrastructure to alleviate range anxiety.